Montana METALLIC 400ml

High-covering abrasion proof metallic effect

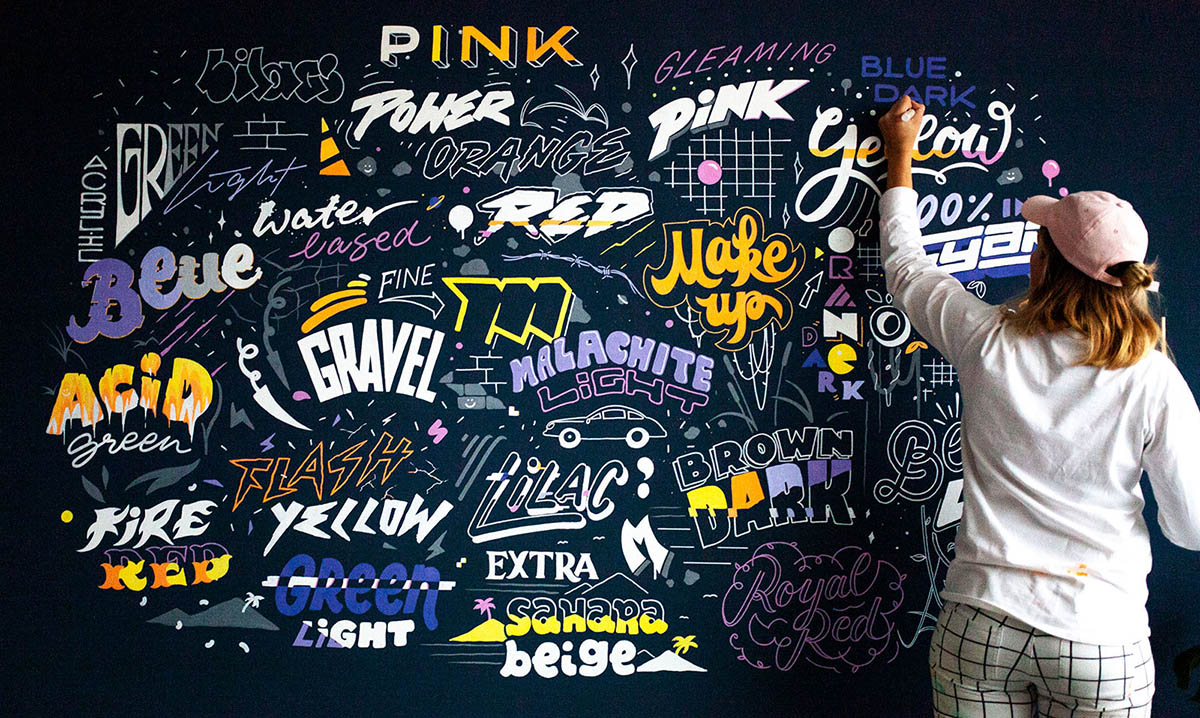

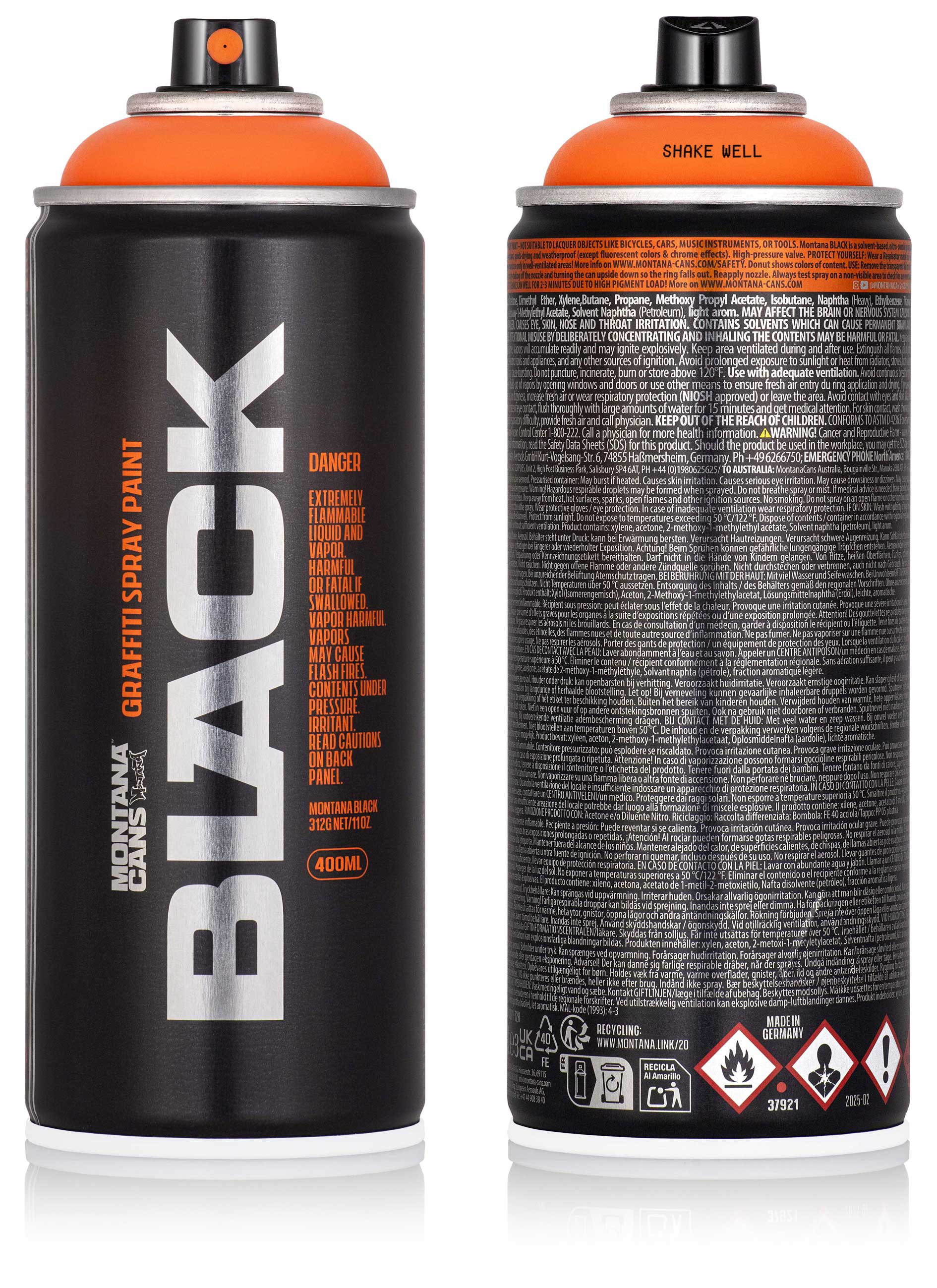

The Montana Metallic Effect Sprays bring state of the art paint technology to traditional metallic effect colors. Loaded with a Montana Standard cap, these cans provide excellent delivery and reliability under medium pressure output. Not only are the Montana Metallic Effect colors ideal for application on functional objects such as bikes and furniture, they can also add a metallic flare to any creative or artistic project on paper, cardboard, primed canvas, wood, glass, metal, ceramics, porcelain, stone, acrylic and other paintable materials. Made from an Acrylic-Nitro Combination base, the paint surface dries to a durable semi-gloss finish which is both hard wearing when cured (24+ hours) as well as flexible. Offering great lightfastness, the Montana Metallic Effect line can also be combined with the Montana GOLD, Montana BLACK and Montana ACRYLIC marker lines.

For best results shake can vigorously for approximately 3 minutes before use and apply at a distance of 15cm - 20cm to a pre-primed substrate. Re-shake between intervals to assure settled pigment is re-mixed. To enhance color result even further, pre-prime substrate with a sim...‹

Produktinformationen "Montana METALLIC 400ml"

High-covering abrasion proof metallic effect

The Montana Metallic Effect Sprays bring state of the art paint technology to traditional metallic effect colors. Loaded with a Montana Standard cap, these cans provide excellent delivery and reliability under medium pressure output. Not only are the Montana Metallic Effect colors ideal for application on functional objects such as bikes and furniture, they can also add a metallic flare to any creative or artistic project on paper, cardboard, primed canvas, wood, glass, metal, ceramics, porcelain, stone, acrylic and other paintable materials. Made from an Acrylic-Nitro Combination base, the paint surface dries to a durable semi-gloss finish which is both hard wearing when cured (24+ hours) as well as flexible. Offering great lightfastness, the Montana Metallic Effect line can also be combined with the Montana GOLD, Montana BLACK and Montana ACRYLIC marker lines.

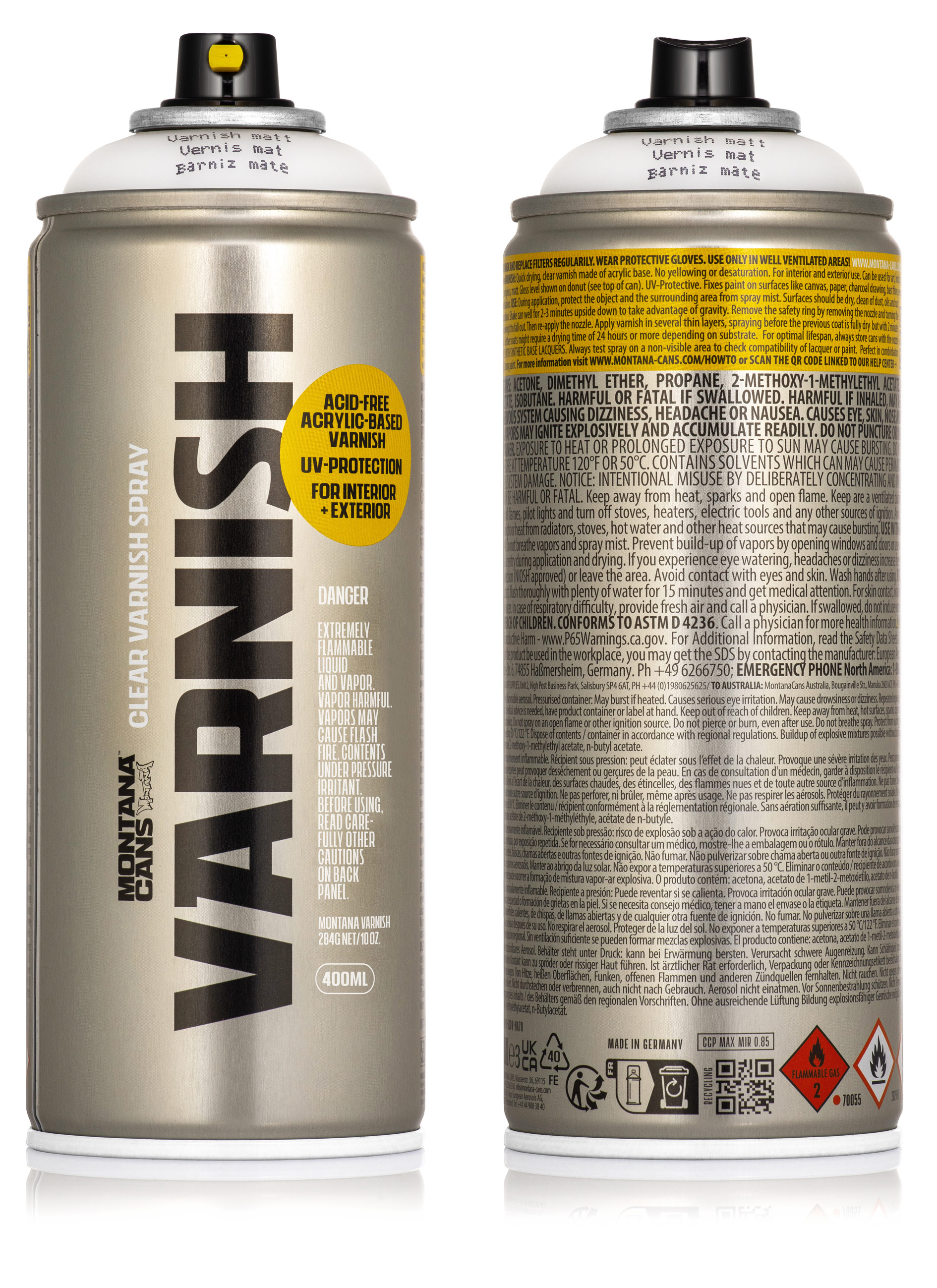

For best results shake can vigorously for approximately 3 minutes before use and apply at a distance of 15cm - 20cm to a pre-primed substrate. Re-shake between intervals to assure settled pigment is re-mixed. To enhance color result even further, pre-prime substrate with a similar Montana GOLD color as base. Apply in thin multiple layers, varying application strokes from vertical to horizontal on each run. Optimum use temperature is between 10 and 15 degrees Celsius. Drying time is normally around 10 mins for dust dry, 20 minutes for touch dry and 24 hours for total curing. Please note drying times vary subject to room temperature and moisture levels. To protect your artwork to its fullest, apply Montana spray Varnish in Gloss, Semi-Gloss or Matt once Metallic Effect colors have dried and cured. We do not recommend objects painted with Metallic Effect colors be exposed to high temperatures over 80 degrees Celsius.

TECH & EFFECTS Broschüre herunterladen:

| Color Shades: | 15 |

|---|---|

| Content: | 400ml |

| Gloss Level: | Seidenmatt |

| Lacquer Base: | Nitro-Acryl-Combi |

| Valve System: | Medium-Pressure |